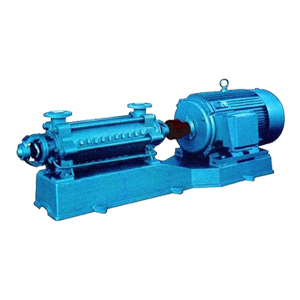

DG type boiler feed pump

Product overview

DG type boiler feed pump is a single suction multi-stage sectional centrifugal pump, which can be used to transport clean water or liquid with physical and chemical properties similar to clean water, suitable for medium and low pressure boiler or secondary high pressure boiler feed water, also suitable for high pressure water supply and drainage in factories or cities.

Product features

It has the advantages of high efficiency, wide performance range, safe and stable operation, low noise, long life, convenient installation and maintenance, etc.

Main Application

DG series pump is especially suitable for boiler water supply, also can be widely used in pressure vessel water supply, hot water circulation, high-rise building water supply, farmland irrigation, fire booster, hydraulic flushing, food, brewing, medicine, chemical industry, aquaculture, environmental protection and other industries.

Model Implication

Technical Parameters:

CapacityQ:6—55m3/h

Head H:46—380m

Speed n:1450—2950r/min

Temperature range:-10—80℃ Diameter:φ40—φ100mm

Structural Features

The rotor part of DG type boiler feed water pump is mainly composed of impeller, shaft sleeve, balance plate and other parts installed on the shaft. The number of impeller is determined according to the series of the pump. The shaft parts are fastened with flat keys and shaft nuts so that they are connected with the shaft as a whole. The entire rotor is supported by rolling bearings or sliding bearings at both ends. Bearings according to different types, are not subjected to axial force, the axial force by the balance plate balance. Pump in operation allows the rotor to move axially in the pump shell, can not use centripetal bearings. The rolling bearing is lubricated with grease, the sliding bearing is lubricated with thin oil, and the oil ring is self-lubricated, and the circulating water is cooled.

DG type boiler feed water pump inlet and outlet are vertical upward, through tightening the bolt to pump the inlet section, the middle section, outlet section, bearing body and other parts of the pump shell connected into one. Choose the pump series according to the head of the pump.

There are two types of shaft seal: mechanical seal and packing seal. When the pump is sealed with packing, the position of the packing ring should be placed correctly, and the tightness of the packing must be appropriate, so that the liquid can ooze out drop by drop. Pump various sealing elements installed in the sealed box, the box through a certain pressure of water, the role of water sealing, water cooling or water lubrication. A replaceable sleeve is installed at the shaft seal to protect the pump shaft.

The sealing surface between the inlet section, the middle section and the outlet section of the DG boiler feed pump is sealed with molybdenum disulfide grease. The sealing ring and guide vane sleeve are installed between the rotor part and the fixed part to seal. When the wear degree of the sealing ring and guide vane sleeve has affected the working performance of the pump, it should be replaced.

Installation instructions

In addition to meeting the general installation technical requirements, attention should also be paid to the following points when installing this type of pump:

1.When the motor and the pump are installed together, the pump coupling end should be pulled out axially, and the end clearance value of 3-5mm should be left to ensure the axial clearance value between the pump and the motor couplings. Note: Make sure the bottom plate is leveled and the levelness of equipment is good before grouting Caution: Coupling adjustment must be correct for successful installation and flexible couplings must not compensate for any apparent misalignment. Disorders may cause rapid Wear, noise, vibration and damage to equipment. Therefore, the coupling must be adjusted within the limits given. Caution: measures must be taken to support the pump inlet and outlet pipeline to prevent excessive pump inlet and outlet load

2.The center line of the pump and the motor shaft should be on the same horizontal line.

3. The pump can only bear its own internal force, can not bear any external force.